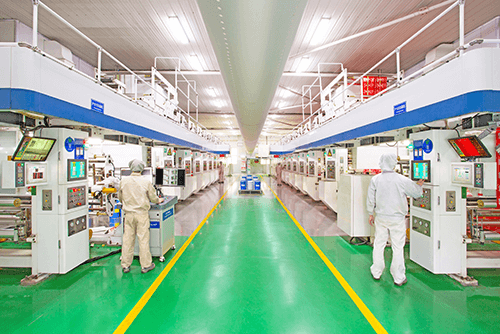

Advanced Facilities & Sufficient Capacity

Ruihong Packaging possesses a wide array of state-of-the-art facilities , including advanced film blowing machines, printing equipment, laminating machines, slitting machines, bag-making machines, injection molding machines, and quality inspection devices. These cutting-edge machinery ensures that our bags are delivered to customers with the highest standards of quality and reliability, meeting diverse requirements from different clients.

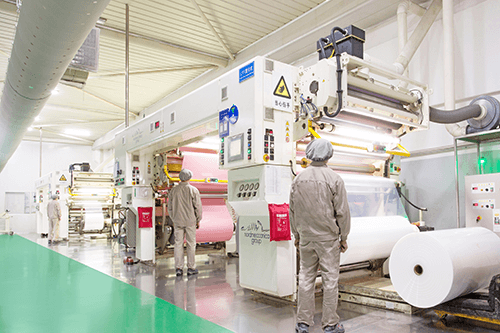

Our Film Blowing Equirements

Our film blowing machines serve as the foundation for providing essential materials such as PE (polyethylene) and CPP (cast polypropylene), significantly reducing lead times in pouch production.

Coex-3 Layers Film Blowing

- Automatic Resin Mixing

- Online trim recycle

- Produce PE film, CPP film in house

- Capacity: 12,000 Tons/Year

Casting Film / Sheet

Casting film machine, also known as a cast film extrusion machine or cast film line, is used to produce thin plastic films through the casting process.

- Coex-3 layers Cast film – 1 Unit

- Thermoform Sheets – 1 Unit

- CPP/CPE film available

- PP,PS,PLA sheets available

- Capacity: 10,000 Tons/Year

Coex-5 Layers Film Blowing

- Widely for high barrier requirements

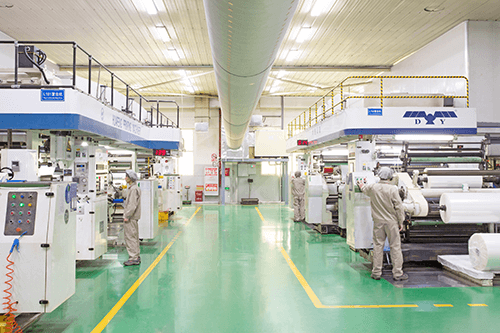

Our Printing Equirements

Rotogravure printing, we use advanced printing machine-BOBST, improve the printing quality.

Automatic Ink Dispensing System

Casting Film / Sheet

Casting film machine, also known as a cast film extrusion machine or cast film line, is used to produce thin plastic films through the casting process.

- Coex-3 layers Cast film – 1 Unit

- Thermoform Sheets – 1 Unit

- CPP/CPE film available

- PP,PS,PLA sheets available

- Capacity: 10,000 Tons/Year

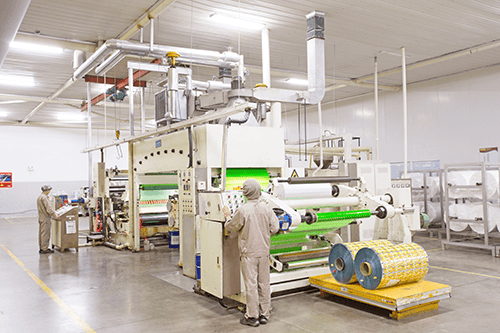

Our Lamination Equirements

We employ various composite methods to meet the diverse requirements of different products. These different methods of composite manufacturing allow us to tailor the properties and characteristics of our products to specific needs.

- Automatic Adhesive Mixing

- Automatic Viscosity Control

- Capacity: 530 Million Meters/Year

Aging Room

- 8 Individual Aging Chambers

- Automatic Bar-Code Control System

- Automatic Aging Time Control

- Automatic Temperature Control

Extrusion Lamination

Single Extrusion : 1 Unit

Solventless Lamination

Duplex : 3 Units

Dry Lamination

Dry lamination is involves bonding layers of materials together using a dry adhesive, typically in the form of a film or powder. This technique is commonly used in the printing and packaging industries to create laminated structures with enhanced strength, durability, and barrier properties.

Duplex : 6 Units

Our Slitting & Bag Making Equirements

Sufficient slitting machine and bag making machines to ensure our production capacity.

Slitting

- Slitting Machine – 5 units

- Laser Score – 4 units

- Capacity: 300 Million Meter/Year

Bag Making

- Stand pouch, 3-Sides – 24 Units

- Center Seal – 2 Units

- Flat Bottom – 5 Units

- Bag in Box – 1 Unit

- Capacity: 300 Million Meter/Year

Spout Welding

- Auto central spout welding – 20 Units

- Auto corner spout welding – 4 Units

- Manual spout welding – 90 Units

- Capacity: 500Million PCS/Year

custom stand up pouches

Custom stand-up pouches are bags that have a support structure at the bottom and are able to stand on their own, and are suitable for packaging a variety of products such as food, daily necessities and industrial products.

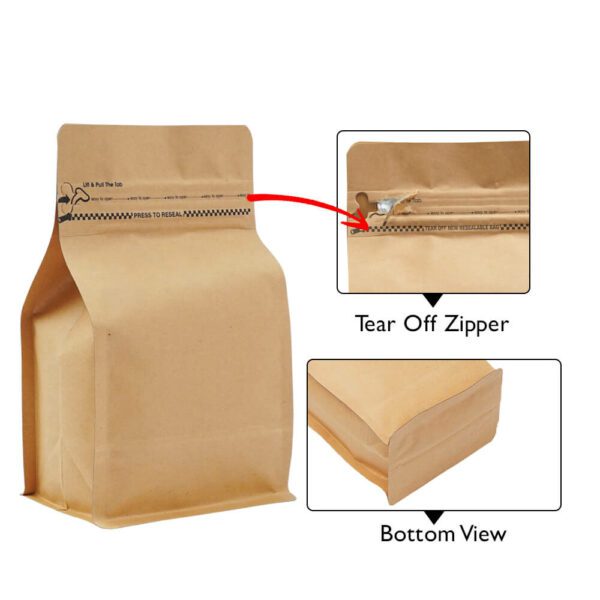

custom flat bottom pouches

Custom Flat Bottom Pouches are bags with a flat bottom that can stand on its own and are suitable for the packaging of various powders, liquids, granular products and daily necessities.

custom three side seal pouches

Custom three side seal pouches are a kind of packaging bags that are individually designed and made according to the specific needs of customers with three sealed sides and one open side.

Contact Ruihong packaging

Address:

T12 Building,Zhuihui New Town, Jihua 1st Road, Chancheng District, Foshan City, Guangdong Province, China.

-70x52.png)