Ruihong Industry & Trade has over 20 years of experience in spout bag manufacturing. We are a very professional spout pouch manufacturers, spout bag factory and spout pouch wholesale. We provide custom spout pouch suitable for all sizes of industries. No matter what style of custom spout bag you need, we can meet your needs. Please let me know your needs and we will respond to you within 24 hours.

Chapter 1: What is a Spout Pouch?

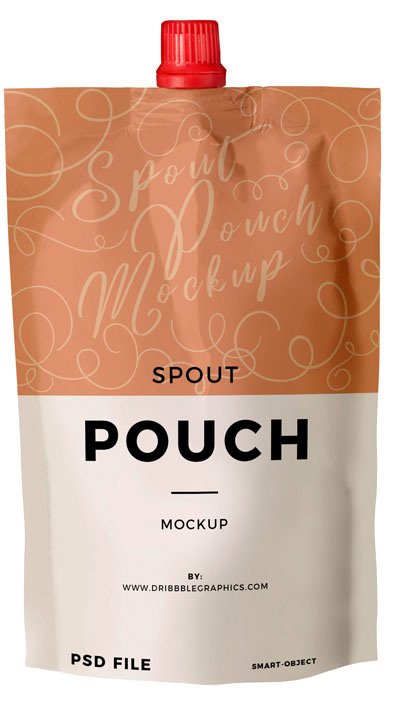

Spout Pouch is a kind of packaging method developed on the basis of stand-up pouches, which is mainly used for packaging of liquid and semi-solid products.

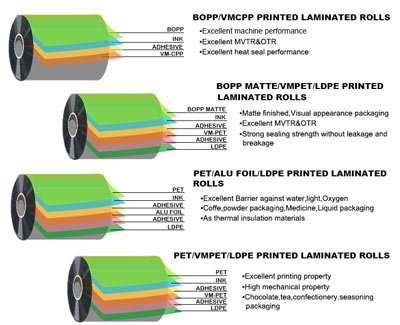

The structure of Spout Pouch is mainly divided into two parts: Spout Pouch and Stand up Pouch. This form of packaging combines the bottom support function of the traditional stand-up pouch and the convenience of the nozzle, making the product more portable and easier to use. Spout pouch material are usually multi-layer composite plastic materials, such as PET//NY//PE, NY//PE, PET//AL//NY//PE, etc. These materials not only ensure the strength and durability of the packaging, but also have good sealing and barrier properties.

Chapter 2: What are the applications of Spout Pouch?

Spout Pouch has a wide range of applications in several fields, including food, daily cosmetics, and medical supplies. Its portability and ease of use make it an ideal packaging choice in these areas.

Food industry applications

- Juices and sports drinks are one of the most common applications for Spout Pouches. Due to their self-supporting and portable nature, Spout Pouches are ideally suited for the packaging of these beverages that need to be carried frequently. For example, juices and sports drinks in Spout Pouches offer great convenience for consumers during outdoor activities or at the gym.

- Dairy products and health drinks are also important applications for Spout Pouches. These products often require better sealing and freshness, and Spout Pouches are designed to meet this need. Spout Pouches effectively insulate air and extend the shelf life of the product.

- Suckable jellies and condiments are also packaged in Spout Pouches. For gelatinous foods such as jelly, Spout Pouches are not only convenient to eat, but also ensure that the contents do not easily leak. For condiments such as ketchup or cooking oil, the Spout Pouch design makes access easier and more hygienic.

Daily Cosmetics Applications

- Personal care products such as shower gels and shampoos have also begun to use Spout Pouch packaging. This form of packaging is not only easy to carry and use, but also reduces the use of packaging materials, in line with the trend of environmental protection.

- Some non-food daily products, such as detergents and personal care products, are also gradually adopting Spout Pouch as a packaging method. These products usually require packaging with a certain degree of sealing and moisture resistance, Spout Pouch in this regard excels.

Pharmaceutical applications

- Spout Pouches are increasingly used in the packaging of pharmaceuticals and healthcare products. For liquid medicines or health care products that need to be taken several times, the repeated closure function of Spout Pouch is very practical. It not only ensures the sealing of the product after opening, but also makes it easy for patients to carry and take it with them.

Industrial and agricultural applications

- Spout Pouches are also used in the packaging of industrial lubricants and pesticides. In these applications, Spout Pouches are often designed with durable and high barrier material construction to protect the product from the elements.

Spout Pouches are widely used in a variety of fields, including food, daily necessities, cosmetics, and pharmaceuticals, due to their advantages of portability, ease of use, and freshness. With the changing market demand and technological advancement, the application range of Spout Pouch is expected to be further expanded to meet the specific needs of more industries. With over 20 years of experience in the manufacturing of Spout Pouches, Ruihong Industry & Trade offers customized Spout Pouches for industries of all sizes, no matter what style of customized Spout Pouch you need, we can meet your needs. Please let me know what you need and we will get back to you within 24 hours.

Chapter 3: What are the types of Spout Pouch?

There are several types of Spout Pouches, each with its own unique structure and function. Specifics are as follows:

Stand up pouch with spout

- A stand up pouch with spout (Doypack) is a flexible packaging pouch that has a horizontal support structure on the bottom and a spout on the top or side. This type of Spout Pouch can stand on its own and remain stable whether it is opened or not. It is made of multi-layer materials such as PET/foil/PET/PE composite with high barrier and sealing properties, and is suitable for fruit juices, dairy products and health drinks.

corner spout pouch

- This type of Spout Pouch has a corner spout pouch with a beveled opening, which makes it easy for users to pour liquids, and is usually used for packaging some liquid products that need to be used at an angle, such as detergents, edible oils and so on. The beveled mouth design not only facilitates pouring, but also reduces liquid dripping during the pouring process and improves the user experience.

Aluminum spout pouch

- Aluminum spout pouch are generally composed of an outer layer, an intermediate layer and an inner layer. The outer layer is usually made of materials such as nylon (NY) or polyester (PET), which has high mechanical strength and good printing performance. The middle layer is an aluminum foil layer with excellent oxygen and moisture barrier properties, which can effectively block the influence of external gases and moisture on the product. The inner layer is mostly made of polyethylene (PE) or polypropylene (PP) with good heat sealing performance to ensure the sealing of the bag. The addition of an aluminum foil layer not only improves the overall barrier property of the package, but also enhances the protection of the bag against the contents, such as preventing potential damage to the product caused by light and ultraviolet rays.

Transparent spout pouch

- Transparent spout pouch are generally made of multi-layer composite materials, of which at least one layer is a transparent or semi-transparent plastic material, such as polyethylene (PE), polypropylene (PP), polyester (PET) and so on. These materials not only have good transparency, but also have a certain mechanical strength and heat sealing properties.In order to improve barrier properties and protect contents, transparent spout pouches may be laminated between a transparent layer and other functional layers (e.g., barrier layer, reinforcement layer). For example, the outer layer may be transparent PET to provide a good visual presentation; the middle layer may be aluminum foil or other barrier material to improve oxygen and moisture barrier properties; and the inner layer may be PE or PP to ensure the sealing of the bag.

Flat Spouted Pouch

Flat Spouted Pouches are usually made of multi-layer composite materials, the outer layer may be polyester (PET), nylon (NY) and other materials with good mechanical strength and printability; the middle may contain an aluminum foil layer to improve the barrier properties; and the inner layer is usually polyethylene (PE), polypropylene (PP) and other materials with good heat sealing properties.

The nozzle section is the highlight of this type of packaging, which is usually made of rigid or semi-rigid plastic, such as PP or PET, and is designed in a shape that is flat and easy to open and close. The size and shape of the nozzle can be customized according to product characteristics and consumer usage.

Shaped Spout Pouch

Shaped Spout Pouch typically refers to a type of flexible container, often used for packaging liquids or semi-liquids, that has a spout or nozzle for easy pouring. These pouches are commonly made from materials like plastic, foil, or laminates, and are designed to be lightweight, portable, and easy to use. They are often used in the food and beverage industry, as well as for personal care products like shampoos, lotions, and condiments.

The spout is typically shaped to facilitate a controlled flow of the product, reducing spillage and making it easier for consumers to use the product. The pouches can be designed in various sizes and shapes to suit different applications and can be printed with branding or information to enhance their appeal and functionality.

Chapter 4: Benefits of using Spout pouches?

The use of spout bag as a method of product packaging, especially for liquid or flowable solid products, has multiple benefits. Specifically, they are as follows:

Customization

Spout bags offer a high degree of customization options, including different colors, shapes, sizes, materials and print designs, which helps in brand differentiation and marketing.

Material Versatility

Spout bag can be made from a wide range of materials such as polyethylene (PE), polypropylene (PP), nylon (NY), polyester (PET), etc., as well as their composites, which allows them to offer appropriate barrier and chemical resistance depending on the product requirements.

Wide applicability

Spout bags are suitable for a wide range of industries, including food, beverage, cosmetics, pharmaceuticals, industrial products, etc., providing packaging solutions for different types of products.

Environmental Advantages

Although spout bags are mainly made of plastic, more and more manufacturers are starting to use recyclable or biodegradable materials to produce spout bag in order to minimize their environmental impact.

Cost Effectiveness

Spout bags are often produced with a high degree of automation, which can reduce labor costs. Their lightweight nature also helps reduce transportation costs.

Portability

Spout bag are often designed with convenient carrying handles or designs that make them easy for consumers to carry and use, perfect for fast-paced, on-the-go lifestyles.

Ease of Use

The nozzle design allows the user to easily squeeze out the contents without having to pour, reducing drips and waste during use, and is especially suited for children, the elderly, or the physically challenged.

Freshness

Spout bags can be designed to be used up in a single use or closed for multiple uses. Spout bags with sealed lids can be re-closed after use to keep the remaining contents fresh and extend product shelf life.

Reduces cross-contamination

Compared to multi-use containers, personal use spout bags reduce the risk of cross-contamination, especially in food and pharmaceutical applications.

Adaptation to automation

The design and manufacturing process of spout bags is easily integrated with automated production lines, increasing productivity and packaging speed.

Custom spout pouch combine portability, ease of use, freshness, customization, material versatility, environmental benefits, cost-effectiveness, automation adaptability, and broad applicability to become a popular packaging option. With more than 20 years of experience as a custom spout pouch manufacturer, Ruihong Packaging can custom spout pouch with different features and materials according to your industry.

Chapter 5: Factors to Consider When Choosing a Spout Pouch

One of the mistakes you can make when buying spout bags for packaging your products is to overlook the factors that influence the choice you make. You do not need to worry about these factors. This study guide has conducted quality research to ensure that you come up with reasonable answers to questions about the factors that influence your choice of buying spout bags.

Budget

Spout pouch bag It is important for any business that wants to flourish to calculate the financial outlay of the business.Before choosing to buy spout bags for your products, you should check that you have the budget and the financial capacity to do so. If your budget is at an average level, then you need a suitable packaging material. Spout bags are the best option because they are reusable and can also be resealed before final and full consumption. They are also dynamic as they can be used to fulfill different purposes.

Safety and durability

It is a correct concept that any so-called packaging must be secure and durable.However, the measure of stability and durability depends on the type of commodity.

While some foods will spoil when exposed to heat or light, others may not. In other categories, bread, donuts and other baked goods (including vegetables), and raw foods such as fish and meat will certainly age faster than expected when exposed to oxygen. The result of this perspective is an understanding of the nature of the product and the specific type of durability and safety required for long-term preservation.

Spout pouch material must be user-friendly

With spout bags Since the ultimate goal of every product is the consumer, the spout bag material must be easy to use. The way the spout bags open, the way the contents are discharged from the spout bags, and other related uses of the spout bags should be self-explanatory and easy to use by people of all ages.

Continuous availability of the selected product

One of the problems that users of spout pouches usually encounter when choosing a packaging material is the lack of availability when the need arises. This problem becomes acute because consumers have become familiar with the products they purchase being packaged in these spout Pouches. Sudden replacement of spout Pouches due to scarcity of spout Pouches will definitely lead to a drop in profits and sales as consumers are not yet familiar with the new packaging material. Therefore, before choosing a spout Pouch, make sure that spout Pouches are in continuous production and are usually in guaranteed supply when there is a demand for them. To find out this information, you need to ask the spout Pouch supplier about the total number of spout Pouches they can supply you with. If this number matches the quantity of your merchandise, you can use spout Pouches. On the other hand, if it does not match the number of items you have, you need to keep looking for a supply that will meet your expectations.

Law-abiding behavior by spout Pouch suppliers

Spout Pouch that are found to be in serious violation of the law can result in severe penalties that can lead to bankruptcy and huge financial losses for your company. Therefore, it is very important to know whether your supplier is complying with the laws and principles that guide the production and supply of spout pouch material. To find this out, you can either explicitly ask the supplying company any legally binding questions, or you can investigate the company’s past dealings on your own. At Ruihong Industry & Trade we ensure that all our business and production practices comply with all recognized and established legal bodies and regulations.

Request for Prototypes before Making Orders

Before you order the spout Pouch of your choice, it is a good idea to request that a prototype of the spout Pouch be sent to you. After obtaining the prototype, you can verify the suitability of the size, color, your own brand name and graphic design of the area where it will be made, the strength and elasticity of the spout Pouch and other equally important criteria. After this is done, you can now choose the dynamic spout Pouch as it has multiple advantages and is also suitable for the kind of thing you want to use it for. There is a reasonable range of Spout Pouches that can perfectly fulfill your expectations. You just need to check them carefully.

Transportation and mobility

Ordering spout pouch material without checking transportation costs and mobility status would be making a very serious mistake. Transporting a product from one destination to another may incur more costs than planned, and if the product (i.e., the spout pouch material) proves to be too heavy and space consuming, it should be discarded. Spout pouch material that is efficient for transportation and storage should be used. Spout Pouches are designed with efficient transportation in mind. Therefore, buying the right spout Pouch is the best idea when it comes to product packaging. Having understood the factors to consider before buying spout Pouches in the market, this study guide will continue to provide you with quality knowledge about spout options in the technical field.

Chapter 6: Spout Pouch Vs Other Rigid Packaging

In this chapter, this study will analyze other packaging materials in comparison to spout pouches based on the criteria that spout pouches may have and come up with which packaging material is better.Other rigid packaging materials commonly found in the packaging industry are bottles and plastic rubber.

These are the standards of justification and assessment below.

Convenience Factor

Since the final end point of all goods is in the hands of the consumer, it is important to know whether the spout pouch material is conducive to handling by the consumer. In terms of weight and shape, bottles and rubberized plastics have been heavily criticized because they are not easy for consumers to carry. Ask a group of young boys to carry cases of bottled drinks and you will see how tired they will get. This is because the bottles themselves are heavy and their shape makes many of them not easy to carry. It is easy to carry one bottle of drink, but if you have to carry four bottles or a certain volume of plastic bottles, it becomes very difficult or impossible for an average person.

On the other hand, Spout Pouches are very easy to hold because of their lightweight material composition which makes them squeezable and easy to carry. A person of average physical strength can easily hold more than four spout Pouches containing any product with his bare hands.

In some cultures, the use of bottles for beverages conjures up images of alcoholism and capricious living, and the use of spouted pouches can serve as an alternative to decency in product packaging.

Plastic rubbers use more than 60% more plastic material than spout Pouches. To save you money, you can use spout Pouches not only because they are cheaper and faster to produce, but also because they make your products last longer and your brand image more visible.

Flexibility

Good spout pouch material should be flexible in the first place. Materials are not fragile when they are flexible. Spout Pouches are undoubtedly perfect in the flexibility test because they can be squeezed without losing the contents of the package or being affected by food spoilage factors. Squeeze a spout Pouch and it will return to its normal smooth and well-arranged texture. On the other hand, there is no doubt that bottle packaging does not seem to meet the flexibility criteria. If you try to squeeze the bottle spout pouch material, you are likely to damage the material and lose its packed contents.

On the other hand, plastic rubber, while not fragile, has its own negative effects. If you squeeze plastic rubber, it will look worn and unsuitable for retail shelves. It is also susceptible to oxygen and light, which can be very detrimental to the shelf life of your food.

Comparison of the Ground of Freshness and Preservation

The ultimate goal of all spout pouch material is to protect the product from penetration of factors such as odor, light, oxygen, and dust, thus ensuring the longevity of the product. Stand-up pouches have been found to be very effective in ensuring long term freshness and shelf life of food products. The inner and outer layers of the spout Pouch make it cool and suitable for edible products and keep them absolutely safe from the hazards of food and beverages.

Whereas, after opening a bottle or a rubberized package, air, dust and bacteria may enter the container and cause the food to spoil quickly. But with Spout Pouches, the freshness of the product is guaranteed even after the first opening.

Viable for Health Reasons

What’s the point of using a spout pouch material for your food if it’s prone to injuring you? Spout Pouches have been proven to survive in the event of an accident or any damage because they are flexible, squeezable and unbreakable, and they don’t cause injury to the operator. If you have to think about avoiding injuries when getting your spout pouch material, then you don’t have to go far, as long as you have the perfect material in your spout pouch.

On the other hand, if an accident occurs during transportation, the bottles used for packaging are sure to break, which can cost you a lot of money and financial losses. Moreover, if you want to use spout pouch material for beverages (e.g. alcoholic or non-alcoholic beverages), it is better to use spout pouches; people can easily cause great damage to their opponents with the bottles; it can even puncture the operator’s hand if not handled properly. On the other hand, the spout Pouch proves to be the most viable and healthy option as it is smooth and completely harmless to human skin.

Storage Advantage to Consider

Studies have found that most Spout Pouch items are always much lighter than the bottle or plastic itself. This means that most of the time, when goods are moved from one place to another, energy and fuel are usually used mainly on the spout pouch material rather than the product itself. This definitely goes against the laws of business efficiency. The same applies to warehouses and storage facilities, where the space used to store products packaged in rubberized plastics and bottles is always larger than that of products packaged in spout Pouches. This is because they cannot be squeezed and their shape does not maximize the use of space.

On the other hand, spout Pouches are very lightweight, which brings ease of transportation and increased storage efficiency due to their lightness and flexibility.

After learning that spout Pouches are, in comparison, much better than other traditional and rigid packaging, there are more important things you need to learn. This will help you gain extensive information and adequate knowledge.Ruihong Industry & Trade has over 20 years of experience in spout bag manufacturing. We are a very professional spout pouch manufacturers, spout bag factory and spout pouch wholesale. We provide custom spout pouch suitable for all sizes of industries. No matter what style of custom spout bag you need, we can meet your needs. Please let me know your needs and we will respond to you within 24 hours.

Chapter 7: Spout Pouch Material Choice

Predominantly, spout pouch are made from polyethylene which comprises plastic elements. In some cases, to make it more puncture-resistant, this essential material make up may be combined with other elements like a metalized PET in the inner layer or aluminum foil too.

Spout PouchThe manufacturing process ensures the production of the combined material elements above result to a spout pouch that is absolutely secured from the invasion of oxygen, vapor, pests, insects, germs, light, specks of dust, and moisture.

They have enough space in the body to serve as a platform where you can print your brand names, graphics, design, and logo.

For the best material choice when it comes to product packaging, spout pouch is second to none in that it specifically designed to meet all the criteria of a perfect packaging for any use and in any climatic condition. It has no weakness at all. It is very dependable and offers durable longevity to your product.

Chapter 8: Spout Pouches FAQs

This chapter will provide quality answers to the questions that are troubling you.

1. What information should I have before requesting a quote for spout Pouches?

The information required is the basic information about the Spout Pouch including Spout Pouch size, Spout Pouch graphics, Spout Pouch add-ons and options, Spout Pouch quantity.

If the information is not clear enough, contacting the Foshan Ruihong Industry & Trade sales team will certainly help to answer all your questions.

2. What is the minimum quantity of spout Pouches I can order in store at one time?

The minimum order quantity for custom printed spout pouches is between 10,000 and 15,000 pouches. However, this is highly dependent on the number of designs you want to produce.

3. What is the minimum order quantity for custom printed spout pouches?

The minimum order quantity for custom printed spout pouches is between 10,000 and 15,000 pouches. However, this is highly dependent on the number of designs you want to produce.

4. If samples and prototypes are requested prior to purchase, can they be sent to me?

Yes, we can send you samples free of charge if you request them, but you will need to pay for the logistics of the samples.

5. Do you advise your customers on the best spout pouch material for their products?

Yes, we have study guides for all our products. We have a sales team on hand to answer all queries.

6. Can you help me modify the design of the Spout Pouch?

Yes, we can assist in modifying the design.

7. How do I fill and seal the Spout Pouch?

There are two options for this process. One option is to fill the bag through the nozzle.

In this case, the bag does not have any opening and remains sealed. The other option is to fill the bag.

In this case, after the filling is complete, the nozzle is sealed and the sides of the bag are heat sealed.

8. Can you help me design my Spout Pouch?

Yes, we can. We have a team of professional graphic designers who will work with you to ensure you have a quality design that fits your brand.

9. What process do I need to go through to get my custom printed bags?

The process starts with you contacting our sales team. It is the role of the sales person to present our requirements to you and offer you the most suitable options.

If you already have a design, it is best to send it to us.

We will then send you a soft copy which will show you what your Spout Pouch will look like when completed. If you are happy with the process, we will proceed with the printing.

10. Are any specific heat sealers for me, and if not what are the sealing options?

It is your workflow that conditions the kind of sealing that will be adopted for your spout pouch. If the method of packing is by hand, a table heat sealer will be suitable. But if it is by an automated means that you are packaging, you will need specially designed and computerized heat sealers. Any option you choose can be discussed lengthily with you.

11. Can I specify the materials I want?

Yes. This depends entirely on the cost of the material. We have a team of engineers ready to work with you.

12. Is the product guaranteed?

All of our Spout Pouches are tested to meet quality standards. However, in case of any problem, you’d better contact us within 10 days from the date of purchase.

Chapter 9: Ruihong Packaging Spout Pouches

At Ruihong Industry & Trade, we are committed to giving our clients the very best. We give meaning to business as we have teams that are prepared to act based on the answers you give to the following questions.

- What are the products that you require us to package for you? Are they edible products? Or drinks?

- What method of filling do you want and what method of dispensing do you want for your product?

- What will the temperature of the content to be packaged be at the time of filling?

- Which direction of the spout pouch do you want the spout to face?

- In what shape or form will you like your spout pouch to be designed in?

- What kind of delivery method do you want?

At Ruihong Industry & Trade, your response to all of these questions guides all our conducts in ensuring that you have the best product in the market.

Conclusion

Ruihong Industry & Trade has over 20 years of experience in spout bag manufacturing. We are a very professional spout pouch manufacturers, spout bag factory and spout pouch wholesale. We provide custom spout pouch suitable for all sizes of industries. No matter what style of custom spout bag you need, we can meet your needs. Please let me know your needs and we will respond to you within 24 hours.

Contact Ruihong packaging

Address:

T12 Building,Zhuihui New Town, Jihua 1st Road, Chancheng District, Foshan City, Guangdong Province, China.

-70x52.png)